3D Portable CMM Inspection Services

3D Portable Inspection Services

We are Services Provider of 3D Portable Inspection Services, 3D Portable CMM Inspection Services, Portable CMM Arm Services, Inspection Services, 3D CMM Services and our set up is situated in Pune, Maharashtra, India.

Have a project that needs only a few uses of a portable CMM, portable 3D scanner or laser tracker? Your FARO® equipment being serviced? Not ready to make a large capital investment in equipment? We can help – our knowledgeable staff has actual project experience with the equipment we provide.

Our Portable Equipment Rentals:

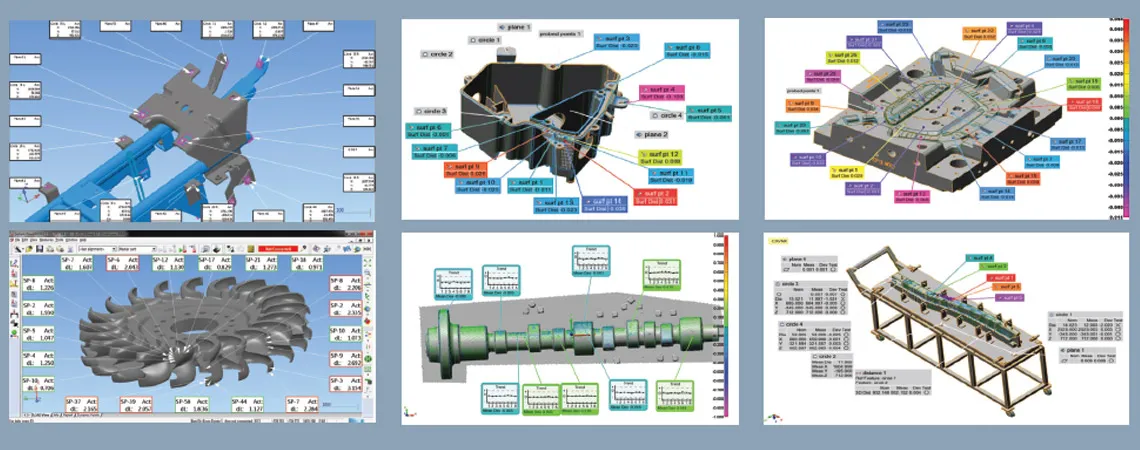

The FaroArm is a portable coordinate measuring machine (CMM) that allows manufacturers easy verification of product quality by performing 3D inspections, tool certifications, CAD comparison, dimensional analysis, reverse engineering, and more. The all-new FARO Edge is the most advanced, state-of-the-art FaroArm ever produced.

The FARO Scan Arm combines all of the advantages of the Faro Arm with a hand held laser scanner and is the perfect contact/non-contact measurement system. Unlike other scanning systems, the Scan Arm’s hard probe and the Laser Line Probe can digitize interchangeably without having to remove either component. Users can accurately measure prismatic features with the hard probe, then laser scan sections requiring larger volumes of data — all in one simple tool.

FARO Laser Tracker- perform 3D measurements with a high degree of precision and speed by using an ultra-precise laser beam to measure objects (0-72 meter range) and an accuracy of 17 microns over a distance of 20. Our laser trackers are able to capture and interpret 3D shapes with respect to any chosen coordinate system, and are extremely portable for infield service work.

We offer daily, weekly, monthly or annual rentals for our FARO portable devices. We can also provide full services.

Contact Type Part Measurements. (Inspection Range 0.1 Mtr upto 4 Mtrs).

The instrument 3D portable CMM Arm is used for inspection purpose. which provides inspection solutions from tiny flexible parts to large machined assemblies with high accuracy & constant Repeatability of output readouts.

The purpose of use this instrument for inspection of parts to confirm the actual inspected readings with its base dimensions

it shows an deviation at real time which helps us for rectification & modification for achieving its final functions.

this device is used in different sectors likes Automotive, Aerospace & Defence, Heavy Engineering Components, Industrial Equipments,

consumer goods oil & gas industries, energy & power plants, Automation Industries and many more industries.

This Instrument is portable & easy for transport to any where so it is used for inspection on machines and different locations in

industries. This instrument is used at normal environmental conditions it took less space & less power easy to handle and operate.

This Instruments is Applicable for Resulting

1. Dimension inspection and GD & T evaluation.

2. On machine inspection of manufacturing part.

3. First article sample ( FAS ) inspection.

4. CAD to part comparison.

5. Without CAD Part Inspection.

Application of this instrument for inspection of all types of Jigs & fixtures, Gauges, Dies, Moulds & Industrial products inspections of sheet metal components, plastic parts, fabrication parts.

1

1 2

2 3

3